From physical to virtual

Simulation technologies for industry, from product design and optimization to virtual or augmented reality reproduction of environments, products and processes.

A range of solutions for the reproduction and analysis of products and environments as well as complex processes: technologies for virtual prototyping, training of employees in simulated settings, management of warehouse in augmented reality or of construction site through IoT.

Reproducible tests in the Living Lab

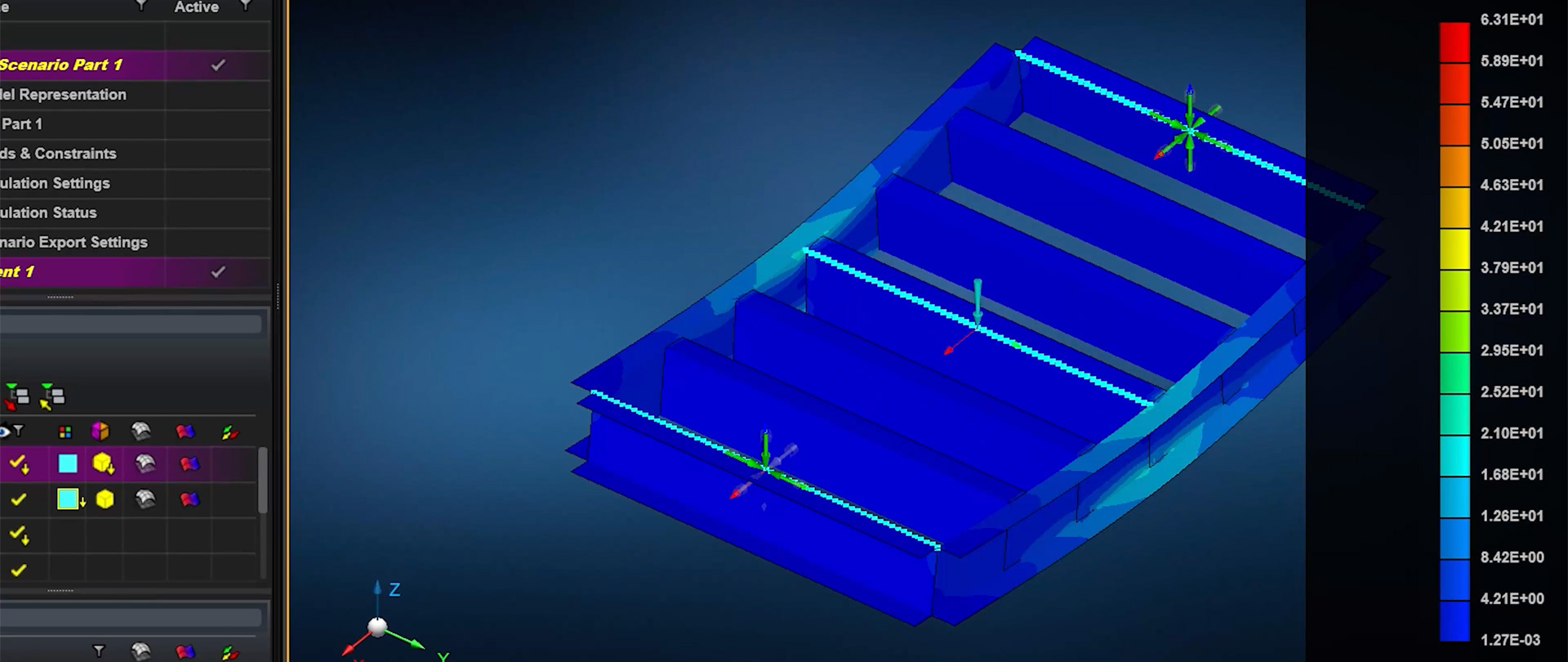

- Product simulation using finite element analysis (FEM - Finite Element Method).

- Integration of FEM simulation and optimization for designing mechanical components.

- Simulation of metal hot stamping process.

- Simulation of pedestrian movement applied to a building evacuation plan.

- Simulation of a logistics hub management process.

- Monitoring and optimization of road vehicle fleet routes.

- Optimization of a building's energy behavior.

- IoT platforms and solutions for the management of construction site activities.

- Augmented reality solutions for maintenance management.

- Collaborative solutions using immersive reality tools.

- Platforms for corporate asset management.

- Innovative solutions for human resource management.

- Support solutions for information security and GDPR compliance.

Benefits for businesses

- Reducing design time and costs.

- Raising efficiency and improving product and process performance.

- Carrying out stress tests safely and at no extra cost.

- What-if analyses and evaluating project performance.

- Improving decision-making activities.

- Carrying out remote and real-time collaboration activities.

- Training employees safely by reproducing environments in immersive or augmented reality.

Partners of the DOS Living Lab

IP4FVG's Living Labs

Book a visit with our experts, come and try the technological solutions present in the demonstrators.