From traditional factory to smart enterprise

Integrated sensor and communication systems to connect plants and exchange data between machinery and machine operators.

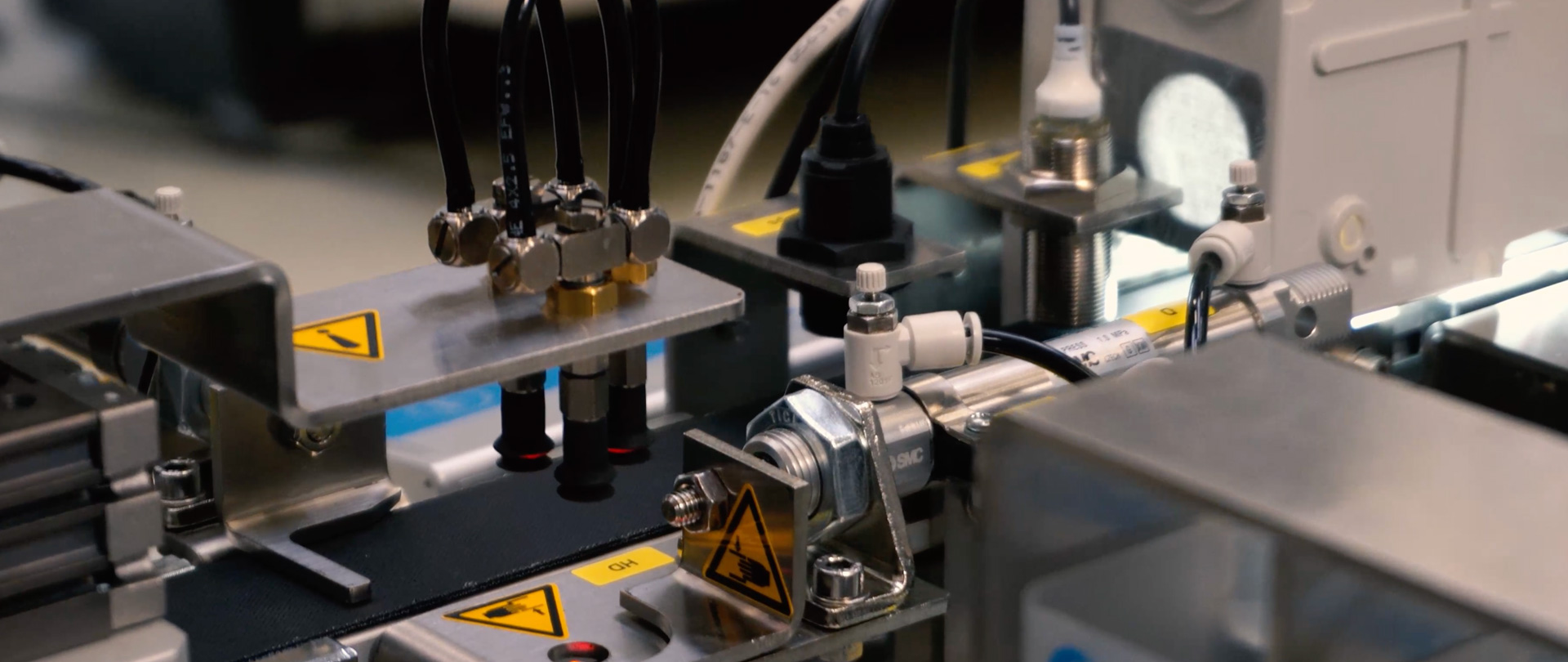

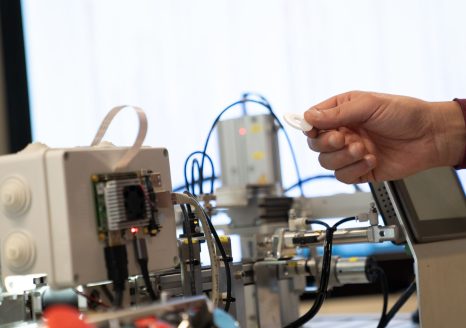

Sensors, retrofitting of industrial machinery, PLCs, gateways and dashboards for remote control: solutions to turn machines into smart and connected equipment, enabling data acquisition throughout the production process

Reproducible tests in the Living Lab

- Dashboards with real-time data from IoT devices for production control and monitoring.

- System for real-time visual control of product quality based on Edge Computing technology and Deep Learning algorithms.

- Predictive maintenance model based on machine data and predictive algorithms.

- Virtual factory model linked to physical control systems (PLCs).

- System for smart monitoring of tanks and digital shadows.

- Retrofitting of industrial equipment.

Benefits for businesses

- Real-time monitoring of plant and production data and parameters.

- Raising production efficiency.

- Reducing time and material waste.

- Automating tasks and collecting production data.

- Analyzing plant information, including remote and real-time data.

- Improving decision-making activities.

Partners of the IoT Living Lab

The IP4FVG

living LABS

Book a visit with our experts, come and try the technological solutions present in the demonstrators.